Taking up the invitation from our SPE mother section, Vienna Basin Section, the day started after a kind welcoming with the annual meeting, gaining an outlook for the upcoming 2021/22 term.

Up next was a guided tour in the newly opened Innovation & Technology Center. Since August 2020, the ITC has been illustrating the state of art in the upstream sector by modern audio-visual systems. Various exhibits and models are demonstrating reservoir exploration, drilling scenarios, sucker rod pump functionality and innovative production concepts. The highlight of the tour was the 7-metre high cylindric 360 degrees screen presenting a mesmerizing cinematic film about OMV’s operations in Austria and all over the world.

Tag: OMV

SCOPE 2018 Résumé

As you all know, the Montanuniversität Leoben SPE Student Chapter was organizing the 2nd Student Congress of Petroleum Engineering under the title “PEoneer – Innovation and New Technology” in Leoben on October 15th-17th.

On Sunday, after the arrival of the incoming students from other chapters, universities and countries, we all had a warm welcoming get together at Bellini in Leoben. It is also called “Leoben oben”, which means Leoben from above and was a nice way for welcoming all participants and showing them the best view over the town. Our team was awaiting every participant with an info folder, including a city map for better orientation and one free drink of choice. Many students from all over the world were exchanging experiences in regard to studies, jobs and future plans. The tables were all pulled together, and everyone was chatting in excitement of the upcoming conference. The SPE Student Chapter Leoben was very eager to make everyone feel welcome and included. As some were tired from either travelling or classes, they went home rather early while others were at no shame to show our guests around Leoben a little while longer through the night. After all, the only thing that’s left to say is that it was a great start for a great conference with great people.

Monday, October 15th, the first official day of SCOPE 2018, started with the registration at the Department of Petroleum Engineering (DPE) building. Each participant and guest of honor received a goody bag filled with important information about not only SCOPE 18’ and the city of Leoben but also about our sponsors and their work, before heading to our organized breakfast.

At 10:00 a.m., we divided the participants into three groups and started our university tour. For each group, the tour included three main stops, but in a different order. First the drilling simulator presented by Senior Lecturer and PhD candidate Anton Lettner, who explained the principle along with the different applications of the simulator. He also focused on how the students use it in order to learn to interpret the different changes on the curves shown on the screens. Our first stop ended with a bonus, since one of our participants had the chance to manipulate the simulator and be in charge as it is in a real life situation.

The second stop was at the Geology and Geophysics Department, where Head of Petroleum Geology – Prof. Dr. Reinhard Sachsenhofer welcomed us with different posters related to the various on-going projects in our university. The participants had the opportunity to have a conversation with him about his experience in the different countries he has worked in and learned some fun-facts about the geology in the Vienna Basin in Austria, the Balkan Region, the Black Sea, China and many more. The tour ended with a visit to the geology museum where beautiful minerals and rocks are exposed for the eye to enjoy.

Our third and final stop was in the new DPE laboratory, where Head of Reservoir Chair -Prof. Dr. Holger Ott along with PhD candidate Pit Arnold not only showed the group the new equipment in the laboratory and their different applications but also presented their research about future core flooding experiments and microfluidics.

We want to thank all the guides for their nicely demonstrated tours. The tour concluded with a joined lunch at the main university.

The main part of the congress was initiated by a great opening ceremony, where the Mayor of the City of Leoben Kurt Wallner, Prof. Dr. Herbert Hofstätter and our President Christoph Flicker addressed warm welcome words to the congress participants.

One of the main highlights of SCOPE were the keynote speeches in which four different speakers from different companies spoke about their approach on how to tackle the challenges of innovation and industry 4.0. Christoph Steiner from PM Lucas Enterprise Limited started off with a technical description of his company’s solution of numerical simulation in naturally fractured reservoirs. Patrick von Pattay, who leads Wintershall’s 4.0 initiative, made it clear that breaking old habits can be disruptive in the short term, but also that rethinking and overhauling long-established processes is necessary for a modern and efficient approach. RAG’s MURAG, an innovative tool to automate processes in production operations, was presented by David Doppelreiter, Head of Business at the Austrian company, before Philipp Lang, Software Engineer at Schlumberger, completed the keynote session with his view on how far the petroleum industry can go in reservoir modelling. We, the SPE Student Chapter Leoben are very thankful for the invested time and work of the speakers and are also very proud to say, that all four speakers are Montanuniversität Leoben alumni.

In the afternoon, Peter Kronberger, Reservoir Engineer at Wintershall, Lukas Mosser, Postgraduate PhD Student at Imperial College, Franz Wohlfart, Deputy Department Director Wells Construction, JV’s and International Projects (Rosneft), Herbert Hofstätter, University Professor in Petroleum and Geothermal Energy Recovery and Hans Peter Messmer, Senior Research Analyst, Energy Studies Department at OPEC, gathered on stage under the spotlight to discuss some important points about the future of the oil and gas industry. The panel was moderated by David Doppelreiter. There was mainly a talk about oil company strategies for digitalization, adapting to new technologies and the impact it has from an economic and social viewpoint. The audience was able to join the conversation with submitting their questions during the panel discussion by means of an online live application, which was managed by the SCOPE 2018 organizing committee, Christoph Flicker, Sharadiya Kozak and Andreas Liegenfeld. This allowed for a variety of answers; the speakers contributed with their opinions on technology related ethics, recruitment, startups and the importance of soft skills.

On Tuesday, October 16th, the paper contest took place. The first phase occurred months before the congress, where more than a dozen participants sent their abstracts to our organizing committee. The abstracts were evaluated anonymously and the four best authors were picked to participate in the paper contest. The second phase occurred during the second day of SCOPE 18’, where these four participants had to present their papers in front of our two judges:

• Luis Lobianco, Technical Sales Engineer for Artificial Lift Systems at Schlumberger, Vienna, Austria.

• Prof. Dr. Herbert Hoffstater, Head of Petroleum Production and Geothermal Energy Recovery Chair at the DPE, Montanuniversitat Leoben, Austria.

The judges evaluated the participants on their presentation skills, their scientific knowledge and on their ability to answer theirs and the audience’s questions.

The ranking of the winner is as follows:

First Place: Hilali Maher

Second Place: Clemens Rainer

Third Place: Artem Karimov

Fourth Place: Alexandra Oberemok

The Student Petroquiz was hosted in the Erzherzog-Johann Auditorium. There was a setup with two teams on stage per round and with a table per team. Three members made up each team. The questions were announced by Mr. Georg Seidl from OMV and Ines Smaoui. The teams started out strongly. However, they started guessing at questions in later stages and members from the audience described as “Jokers” came to the rescue. Eventually, the team “Perdido” emerged as the triumphant winners.

At 6:00 p.m., the Student Congress of Petroleum Engineering Closing and Award Ceremony took place at the Erzherzog-Johann-Trakt Auditorium. It was indeed a great honor and joy and privilege to have Mr. Alexander Gerstner and Prof. Herbert Hofstätter with us and to witness their encouraging speeches as well as their motivational words that pushes as petroleum engineers in general and SPE members specifically to work more for the benefit of our SPE Student Chapter and university. Speeches were followed by an award ceremony for our Paper Contest and Student Petroquiz winners. Each participant was handed a certificate of acknowledgment and other gifts as cash prizes or souvenirs from Leoben and the Montanuniversität of Leoben.

After two successful days of Panel Discussions, Keynote speeches and student contests, an after party was launched at Bodega Central Dancing Leoben. It was a great opportunity for SCOPE participants and organizers to spend more time together and enjoy the last day of the congress before they left on a field trip to OMV Aktiengesellschaft facilities and the head office, hosted by the SPE Vienna Basin Section on Wednesday, October 17th. We hopped on a bus, heading towards Gänserndorf, where OMV-Austria’s Exploration and Production activities are headquartered. The first stop was the in-house core storage facility, where some 50.000 meters of cores from OMV’s assets all over the world are stored and examined. Next stops included the corrosion and metallurgical testing facility, where we got an insight into a lot of different corrosion problems occurring when producing, transporting and refining hydrocarbons. After this, we got a very interesting tour through the water testing lab, EOR lab and PVT lab.

After a delicious lunch in the canteen in Gänserndorf, we resumed with a bus tour through the oil fields around Gänserndorf guided by Well Delivery Manager and SPE VBS President Alexander Gerstner. As we were rolling through the smooth landscape of lower Austria, we got a glance on numerous sucker rod pumps, the water treatment plant in Schönkirchen, gathering stations, EOR facilities, a drilling rig, gas storage facilities and the desulfurization plant in Aderklaa. Furthermore, Mr. Gerstner was giving us an overview of OMV’s history in the regions and some future plans.

Our last stop was the brand-new 3D-Visualization Room in OMV’s head office in Vienna. With this state-of-the-art piece of technology, geologists can visualize complex geological formations and find potential oil and gas deposits that are yet to be drilled.

At this point, we really want to thank the SPE Vienna Basin Section and especially Alexander Gerstner for organizing the field trip and showing us around OMV’s operation in the Vienna Basin. It was really a great experience. We want to especially thank all our sponsors, without their help this event would not have been possible:

Gold Sponsor:

PM Lucas Enterprises Limited

Silver Sponsors:

Greenwell

ILF Consulting Engineers Austria GmbH

Weingut Liegenfeld

MND

RAG & RDG

Schoeller Bleckmann Oilfield Equipment AG

Bronze Sponsors:

TDE Group GmbH

Sirius E.S.

Rohrer Group

Thank you all and see you at SCOPE 2020!

The Organizing Committee:

Christoph Flicker

Sharadiya Kozak

Andreas Liegenfeld

Student Congress of Petroleum Engineering

The event was kicked off for the students by a field trip to the OMV Refinery in Schwechat, in which not only students from MUL, but also from Clausthal (Germany), Moscow, Ufa and Almetyevsk (Russia) participated. We were shown a nice presentation about the refinery, how the process works as well as how OMV innovates and invests in environmentally sustainable technology. Then we boarded our bus and went through the refinery. We realized that the refinery turned into a comprehensible site: Suddenly all the “smoking tall towers” almost everyone knows from their way to the Vienna airport turned into chimneys, reactors, distillation towers and so on. After about an hour, we had seen all facilities, and we could return to the canteen, have lunch and return to Leoben. But on our way to Leoben, we encountered a little surprise:

About halfway to Leoben, the bus suddenly slowed down, and exited the highway for a stop in Ternitz in Lower Austria. To the surprise of the participants, we could arrange a quick visit at Schoeller Bleckmann Oilfield Equipment (SBO), one of the world’s leading manufacturers of special purpose drill string components, such as the basis for downhole motors, non-magnetic drill pipes or various logging and measurement devices. Although due to the current industry downturn the plant seemed nearly dead, we could get a good impression of how things could be here when the demand for high-quality products is high. The tour gave the opportunity to see the whole manufacturing process, starting from the raw steel cylinder over various treatment processes to the precision work of drilling out holes with diameters reaching from a few millimeters up to several inches, which are required to fit in various measurement tools, motors or electrical cables.

After returning from the Field Trip – and introducing our guests to the traditional Leoben semester opening events – we gathered again on Tuesday afternoon for the start of what would become two and a half days of intensive presentations, discussions and networking. The event started with Professor Thonhauser welcoming the guests, talking about the history of our department. His introduction was followed by interesting and inspiring keynote speeches from important and high-ranking industry veterans.

Christopher Veit (OMV), who chose to talk about the successful scientific cooperation between MUL and OMV, was followed by a speech by Gerald Grohmann (coincidentally the CEO of SBO which we had visited just the other day). He introduced the audience to his company’s operations. The keynote speeches were continued by a representative of Rosneft, Franz Wohlfart. He talked about his company, which seems to be quite unknown in Europe, despite being one of the largest oil companies not only in Russia, but worldwide, and more importantly, about the importance of strategic planning, exceeding just the next reporting period. In his opinion, even our industry, which is dominated by significant price fluctuations, has to think in dimensions well exceeding 10 years to position ourselves and to be prepared for the future!

Ted Christiansen of voestalpine Tubulars focused on innovation, and the role of our generation: We will be the ones whose visions will bring the industry forward in the future. He encouraged the audience to think out of the box, be curious and creative, and most of all persistent if we are convinced of an idea! The last keynote was by Kris Ravi, a former Halliburton Technology Fellow, now running his own consultancy, who talked about well integrity.

The day was concluded by a gala dinner in the Congress Leoben. Along with a great selection of typical Austrian food, we could talk and get to know each other. But even during dinner, we had the great opportunity to listen to another great presentation: Philip Keil, a professional pilot with Lufthansa, talked about the techniques pilots use to keep calm even in unusual and highly stressful situations. “Aviate, navigate, evaluate” and a technique called “FORDEC” (acronym for “Facts, Options, Risks & Benefits, Decision, Execution, Check”) does not only help pilots, but they are also things we could use for ourselves. The basic idea behind those models are to have a predefined “checklist”, what has to be done first before doing the next step. It also gives a clear priority to the important things (Aviate, i.e. flying the plane is the key, and only if that is guaranteed, the pilot can go to the next task, which is to follow his route. And only when on this route, he can deal with all the “greater picture”).

Wednesday morning was dominated by a panel discussion between Prof. Hofstätter, Prof. Ott, Kris Ravi (Halliburton), Helmut Langanger (ex-head of OMV E&P) and Matthias Meister (Baker Hughes, Regional Director of SPE) led by Prof. Thonhauser. The motto of the discussion was “Last 60 years, next 60 years”, investigating various aspects of the industry, what led us to the status quo, and more importantly the outlook to the future. While the panelists did not share an opinion on the role of renewables, and how much our own industry should focus on this subject, there was one thing quite clear: The future generation will see some significant changes, but oil will always be important, and a high quality education is the key to success. With this reassuring message, the official program of the 60th anniversary celebration was ended over lunch.

This was the time when the SPE Student Chapter took over, now under the motto “PEfficiency – New Technologies to Improve the Energy Efficiency of the Oil and Gas Industry”. On Wednesday afternoon, Matthias Meister talked about the newest developments in logging while drilling made possible by Baker Hughes, one of the world’s largest oilfield services providers. The second presentation was done by Peter Soroka and Anna Petitt, presenting their company Tendeka, a market leader in the production of completion equipment. They also talked very much about autonomous inflow control devices, a piece of technology Tendeka developed, which is used to control water and gas influx in oil wells. This allows a more efficient production of oil while not having to shut in perforations completely.

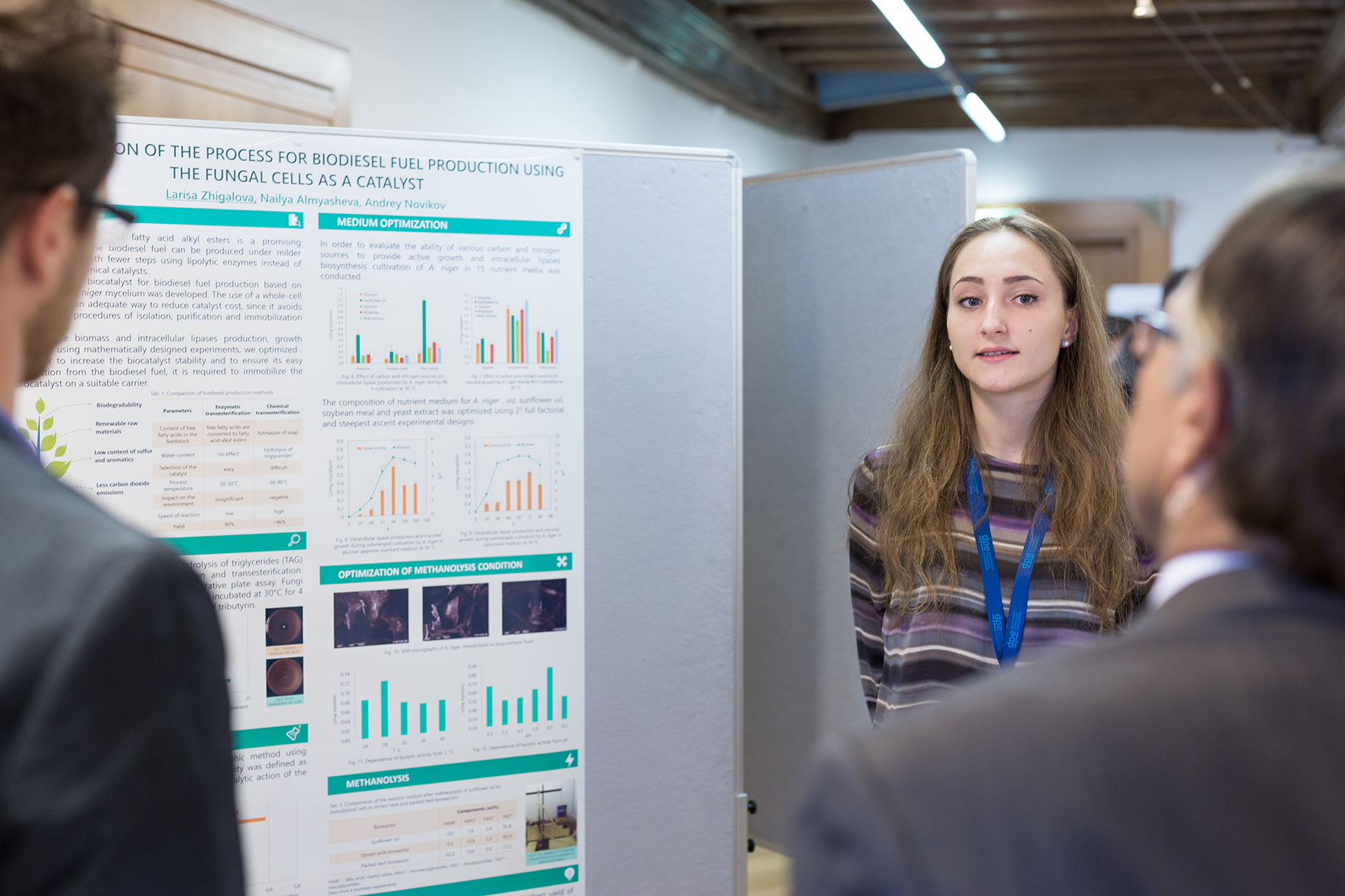

The sessions on Wednesday were concluded with the Poster Contest sponsored by Schlumberger, the world’s largest oil field service provider. 14 contestants from nearly all attending universities competed with interesting topics reaching from reservoir engineering over drilling and production technology as well as pipeline engineering and even alternative fuels. At the end, the proud winner of the contest was Airat Kashkarov, representing Ufa State Petroleum Technological University. Congratulations to him, and of course to all the participants to the Poster Contest for their outstanding research work!

Thursday was again under the patronage of your local SPE Chapter. Our participants could hear an interesting presentation about an exciting technology developed by the Austrian company RAG: The MURAG system, which allows an automatic measurement of the liquid level in a well, which is used to adjust pump speed for an optimized efficiency. The presentation, followed by a nice discussion about the benefits of this tool, was held by Christian Burgstaller, one of the leading developers of the MURAG system. His presentation was followed by the former chairman of the SPE Vienna Basin Section, Reinhard Pongratz. He talked about his own worldwide career with Halliburton, and then OMV as well as within SPE. His speech was a motivation to join SPE and to be active there – as he said, a very rewarding experience, although it takes a certain commitment.

The third presentation of the morning session was then somewhat science-fiction, reminding the audience of the legendary film “Armageddon”: David Kutas and Alexios Koulidis, a recent graduate and a master student of MUL, presented their research about drilling in outer space. A well-prepared and really interesting presentation was followed by a lively discussion, in which pros and cons of such a missions were discussed. While apparently the time for drilling in outer space is yet to come, it needs great visions and free spirits like these two guys to drive development and innovation!

Last but not least, Prof. Helmut Weiss of Montanuniversitaet Leoben’s Electrical Engineering Department introduced us to the electrical engineering of sucker rod pumps and the enormous potential for increasing efficiency on that field!

After lunch, SCOPE was concluded with a fun event called PetroQuiz, which was hosted by our sponsoring SPE Section, the Vienna Basin Section. Under the guidance of a jury of four industry professionals, about 30 participants competed, showing off their knowledge on various fields of petroleum engineering, and our knowledge from drilling, production and facilities, to reservoir engineering, and even our general engineering knowledge was put to the test. The final round was won by the team “SPEcialists”, consisting of students of Leoben and Zagreb university, closely followed by a Russian-German-Ukrainian trio and another team from Leoben.

A great thank you to every participant, making this event possible. At the same time, we would also like to thank all those involved in the planning and execution of this memorable event – organizing the framework, inviting speakers, putting up the questions for the quiz etc. – it could not have been such a great experience to everyone without your input!

Finally, we would like to congratulate our Department of Petroleum Engineering to its 60th anniversary, and wish the department, its members and most all its students a bright future! To many more great years to come!

Field Trip to OMV Refinery and SBO

Arriving there we were greeted by Mr Martin Müller, our tour guide. At first we were invited into the meeting room for a presentation about the refinery, giving us not only a good overview of the processes that happen in a refinery, but also about the in- and output of the refinery, as well as some interesting statistics.

For example, did you know that despite Austria’s reputation of producing hardly any oil 10% of the oil processed in Schwechat actually comes from the oil fields in Lower Austria? Or did you know where the by far largest amount of oil refined in Austria comes from? (If not, you’re probably not the only one. The correct answer is Kazakhstan, by the way.). All the imported oil, we learned today, comes to Austria via pipelines from Trieste in Italy. To transfer the same amount of oil by truck, more than 900 trucks would be required to travel the distance – per day!

Now that we knew where the crude oil comes from, we could start following its course through the refinery. The first step – after leaving the storage tanks (which can store three months’ worth refining, equaling about 2.4 million tons) – is distillation. The crude gets heated up, thus separating its constituents due to the different boiling points. Since the oil is often contaminated, for example with acid components like Sulphur, it has to be sweetened, i.e. the sour components need to be removed in order to avoid corrosion as well as other problems, e.g. harmful exhaust fumes.

Since the refinery cannot create the products in the same proportions as they are required, the distilled and desulphurized products are “upgraded”. This includes thermal and chemical treatments such as cracking and reforming, where the output can be precisely controlled via the operation parameters. This allows to adjust the refinery output to the actual consumer needs. In the case of Schwechat, this is about 40% diesel oil, 20% gasoline (Yes, we actually consume nearly twice as much diesel than gasoline in Austria!) and 10% jet fuel and petrochemicals each. The remaining 20% of the refinery output include for example hydrocarbon products such as bitumen and asphalt, LPG or CNG and byproducts such hydrogen, Sulphur or sulphuric acid, products that are required in large amounts by other industry branches, such as the steel industry.

The last step in the refinery process is the so-called blending. Individual fractions are recombined to achieve certain properties and specifications, such as the octane number for gasoline fuels, or freezing points (for example diesel composition varies between summer and winter to guarantee an optimum efficiency while not risking that the fuel freezes). OMV applies an in-line blending system, which means that the different semi-products are not mixed in a tank using a huge impeller to avoid separation, but by feeding different semi-products directly into the pipes. This has the advantage of being more efficient and at the same time achieving a more homogeneous product.

The now finished products are ready for shipping. They are pumped to the tank farms in Lobau (Vienna), St. Valentin (Upper Austria) or directly to the close-by airport (only jet fuel). From there, they are either distributed onwards using ships, trucks or trains, or directly sold to the consumers.

Passing by refinery on the way to the airport, it appears needless to say that such a plant consumes a lot of energy. Hence OMV has its own power plant on site. The energy created is not only consumed in the refinery itself, but also sold to the surrounding towns. Furthermore, OMV uses the heated water and steam to produce energy, and they also to provide the heat for heating homes and the airport.

Mr Müller also talked about the investments OMV makes to reduce the environmental footprint, and to make the refining process greener. This includes not only converting the generated heat, hot process water and the electricity as energy on site and in the surrounding area, but also the implementation of new technologies, such as the recent reactor upgrade or the ButaMax facility. This facility produces butadiene, a substance required for producing rubber (e.g. for tires). Furthermore, many other industry branches that rely on refinery products, semi- or byproducts are located next to the refinery, rendering transportation nearly unnecessary. For example, Borealis, who produce polymers, are located right beside the refinery itself.

After this presentation, packed with lots of information, we were glad to have a short coffee break before entering the bus and getting the opportunity to see all those facilities we had just heard about in operations. In about 45 minutes, we got a good impression not only of the immense size of the refinery, but also about the facilities it hosts, and their basic working principles.

Soon it was time for lunch, and then to travel back to Leoben, although we encountered a little surprise on our way back…

About halfway to Leoben, the bus suddenly slowed down, and exited the highway for a stop in Ternitz in Lower Austria. To the surprise of the participants, we could arrange a quick visit at Schoeller Bleckmann Oilfield Equipment (SBO), one of the world’s leading manufacturers of special purpose drill string components, such as the basis for downhole motors, non-magnetic drill pipes or various logging and measurement devices. Although due to the current industry downturn the plant seemed nearly dead, we could get a good impression of how things could be here when the demand for high-quality products is high. The tour gave the opportunity to see the whole manufacturing process, starting from the raw steel cylinder over various treatment processes to the precision work of drilling out holes with diameters reaching from a few millimeters up to several inches, which are required to fit in various measurement tools, motors or electrical cables.

OMV Excellence Master Scholarship

Get ready for one of the greatest challenges of our time: the future of energy provision. Receive full funding and support to undertake the Petroleum Engineering Master Degree at Leoben via the OMV excellence Scholarship program.

Apply for the OMV Excellence Master Scholarship today and take your first step towards the perfect career!

10 reasons to apply for the OMV Excellence Master Scholarship:

- No obligation to pay back

- Allowance for living costs and meals for the entire year (€ 490,- per month)

- Allowance for accommodation expenses (€ 340,- per month)

- University tuition fees paid in full (€ 363,36,- + € 18,70,-per semester)

- Funding for additional educational expenses (€ 150,- for books, etc.) / once a semester

- Laptop (approximately € 800,-)

- Support from your OMV mentor

- Guaranteed exclusive internship place

- Guaranteed master’s thesis with OMV

- Close industry contact throughout your studies

Requirements:

- Studying bachelor’s degree course petroleum engineering or an equivalent engineering bachelor’s degree course (technical engineering, mechanical engineering, technical chemistry, process engineering, electrical engineering, building and construction engineering) and planned start for the master’s degree program course petroleum engineering in the winter semester 2016/17 at Montanuniversität in Leoben

- Good academic achievements in the chosen course of study to date

- Excellent English skills

Benefits:

- Comprehensive scholarship package

- Preparatory Intensive Petroleum Engineering Short Course at Montanuniversität Leoben for graduates with an equivalent qualification in Engineering for entry to the Petroleum Engineering Master’s program

- First-class internship in one of OMV’s operational E&P business units

- Mentoring by OMV experts

- Career opportunity in OMV E&P world with early international assignments

- Guaranteed master’s thesis with OMV

Apply now: www.omv.com/excellence-scholarship